For parts thicker than 120 stress-relieving is recommended and 1100ºF is the optimum temperature for tubing applications. Cool slowly in the furnace to 480C followed by air cooling.

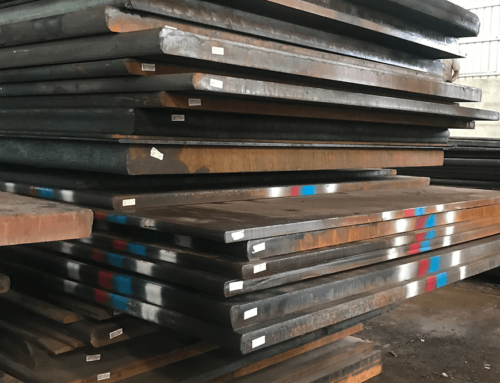

Aisi 4130 Steel 25crmo4 1 7218 708a25 Scm430 Special Steel

AISISAE 4130 and 4140 specifications refer to a chemical composition range only as opposed to both a chemical composition and mechanical property ranges.

Stress relieve 4130 material. The tools products can be finish machined before heat treatment. The material may require a post-weld stress relief heat treatment in certain instances. After welding machining etc provides virtually complete stress relief.

AISI 4130 Steel 25CrMo4 17218 708A25 SCM430 - Special Steel. Carbon steels and alloy steels can be given two forms of stress relief. Stress relieve 4130 tube Metalguy Materials 10 Jun 03 1852 Youll be safest if you can somehow heat all the weld areas to about 1100 deg F for about 30 min.

Do I need to heat treat stress relieve 4130 after welding. It is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. Do not confuse a heat treatment with postweld stress relief.

It is very useful for any mechanical engineer to be aware of 4130 steel properties. Case-hardened components bearings etc. Treatment at typically 600-680C eg.

This is acceptable provided 310 or 312 stainless steel fillers are used. Stainless filler material is typically more expensive. Treatment at typically 150-200C relieves peak stresses after hardening without significantly reducing hardness eg.

Low-hydrogen electrodes are recommended together with preheat at 150 260 º C 300 500 º F to be maintained during welding Cool slowly and stress relieve where possible. It has low carbon content and can be welded easily. Carbon steels may be stress relieved by holding a temperature at 1100 to 1250F 600 to 675C for 1 hour per inch 25 mm of thickness.

Do I need to heat treat stress relieve 4130 after welding. This is acceptable provided 310 or 312 stainless steel fillers are used. Generally the nominal maximum stress that cause this kind of damage in a material may be much lower than the strength of the material normally known as the.

AISI 4130 steel is also good in weldability and the 4130 alloy may be welded by any commercial method. Other stainless steel fillers can cause cracking. Heat the AISI 4130 slowly to 850C and allow enough time for the steel to be thoroughly heated.

Thin wall tubing normally does not require stress relief. AISI 4130 is a chromium-molybdenum steel that is in general aviation use due to its well established heat-treating practices and processing techniques. 4130 steel otherwise known as Chromoly or chromium molybdenum steel alloy is made with 08 to 11 chromium and 015 to 025 molybdenum as strengthening agents.

Steel properties make it a versatile metal especially mechanical properties such as high ductility good weldability and the fact it can be. An OxyAcetylene torch with neutral flame can be used. The heat treatment produces a desired microstructure that changes the mechanical properties of the material to a desired strength and ductility level.

The postweld stress relief is exactly thata method to relieve stresses that are the direct result of the welding process. The datasheet below provides further detail. AISI 4135 has a slightly higher carbon version of AISI 4130.

Other stainless steel fillers can cause cracking. Do I need to heat treat stress relieve 4130 after welding. Thin wall tubing normally does not require stress relief.

AISI 4130 steel is a medium carbon low alloy steel in ASTM A29 standard. First Pre-heating M2 steel to 460-500C then heating 860-900C. After holding it at temperature for the specified time the piece can be cooled to room temperature without the danger of cracking.

4140 steel is also commonly referred to as a chromoly steel or chrome moly steel. Stress relieving offers several benefits. For example when a component with high residual stresses is machined the material tends to move during the metal removal operation as the stresses are redistributed.

Material was mistakenly delivered in annealed condition and cut to size then turned over to us for weldassembly. For stress relieve heating the component to 680-720C and soak well about approximately 2 hours then put in air cool. However it has relatively low carbon content nominally 030 percent so it welds machines and bends almost as easily as 1018 DOM mild steel tubing which has an 018 percent carbon content.

For parts thicker than 120 stress. The 4130 grade of chrome-moly is a high-strength low-alloy HSLA steel that contains molybdenum 015 - 025 percent by weight and chromium 08 - 11 percent by weight as strengthening agents. AISI 4140 is a chromium-molybdenum steel that can be heat treated to higher strength levels or in thicker sections than AISI 4130.

We have a GTAW WPS and a SMAW WPS for 4130 both specifically identify it as applicable to Normalized material. It should be oscillated to avoid hot spots. Some fabricators prefer to use austenitic stainless steel fillers to weld 4130 tubing.

Hardening of M2 tool steel HSS material. You failed to mention exactly what filler metal you used. From material science viewpoint fatigue is caused by the application of repeated loads.

Stainless filler material is typically more expensive. Stress Relieving When parts are heavily machined ground or otherwise subject to cold work stress relieving will be beneficial prior to any hardening. Fatigue weakens the material.

AISI 4130 alloy steel contains chromium and molybdenum as strengthening agents. In these cases AISISAE 4130 and 4140 low-alloy steels are often used because their chemical composition allows them to be heat treated to high tensile strength and hardness. Typical post weld stress relief is required 1100 deg F for 1-hourinch thickness.

Corresponding fillers specifically for welding 4130 is listed in ASM specification 6457A.

Cr12 Steel Gb T 1229 Cold Work Tool Steel Material Special Steel China Supplier Otai Special Steel

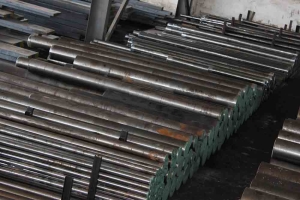

Aisi 4130 Steel 25crmo4 Jis Scm430 Gb 30crmo Songshun Steel

4130 Steel Price Per Kg China Manufacturer

Aisi 4130 Steel 25crmo4 1 7218 708a25 Scm430 Special Steel

Aisi 4130 Steel 25crmo4 1 7218 708a25 Scm430 Special Steel

Aisi 4130 Steel 25crmo4 1 7218 708a25 Scm430 Special Steel

0 Comments