Your question on the stress relief of 316L plate is a good one. CalvinKelly Materials 11 Oct 03 1115.

Allied is the Distributor of Choice for Industrial Automation Control.

Stress relieve 316. There might be some argument for 316 given the way Mo is supposed segregate. But I suppose in order to justify it the design would have to be cuttin it pretty close in regards to the service it will be used for. Stress relieving is applied to both ferrous and non-ferrous alloys and is intended to remove internal residual stresses generated by prior manufacturing processes such as machining cold rolling and welding.

While the 450-750ºF 230-400ºC stress-relief temperatures are recommended for dimensional stability Table 2 there is evidence to suggest that they may not be as effective for plate as using higher temperature that is 1100-1150ºF 590-620ºC that you mention. S tainless stee l 316 is readily brake or roll formed into a variety of parts. The stainless steel 316 was selected for residual stress reduction.

304L or 316L be used particularly if extended stress relief times are required. Ad Wide Selection of Connectors from Marathon Special Products. The grain size is also enhanced and uniformed in this process.

Similar to the annealing process the steel is heated to a temperature just beyond the critical point again the AC3 line and held for a set period of time. It is also suited to stamping heading and drawing but post work annealing is recommended to relieve internal stresses. Allied is the Distributor of Choice for Industrial Automation Control.

One hour of stress relieving at 870C relieves about 85 of residual stresses. As you exhale imagine that youre breathing out stress and tension. Ad Wide Selection of Connectors from Marathon Special Products.

Hot Working of S tainless stee l 316. The resultant composition of CS 316 gives the steel much increased corrosion. Stress relieving at temperatures of up to 425 to 925C will significantly reduce residual stresses which otherwise cause dimensional instability or stress corrosion cracking.

In addition AISI 316 might lead to stress-corrosion cracking or dimensional instability in service after welding so postweld heat treatment is required for stress relief to reduce intergranular corrosion or stress-assisted intergranular corrosion while. The usual steel stress relieving temperature around 1100F 600C does not relieve much stress in austenitic SS but can make things worse by causing intergranular carbide precipitation. Cold working will increase both strength and hardness of S tainless stee l 316.

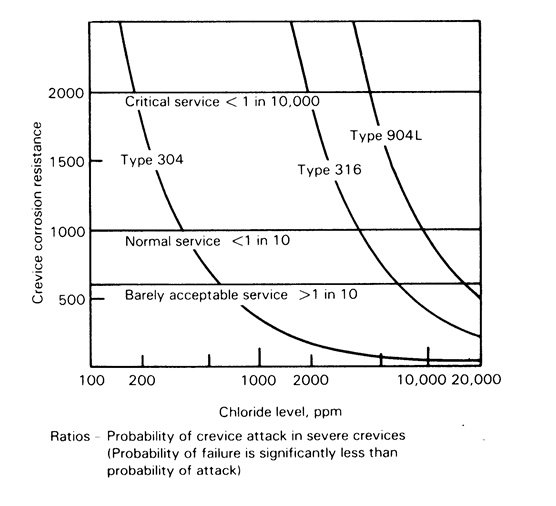

Types 316 and 316L generally contain 2 to 3 molybdenum for improved corrosion resistance. Grade 316 is an improved version of CS 304 with the addition of molybdenum and a slightly higher nickel content. Stress relieving reduces residual stresses avoids stress corrosion cracking improves notch toughness and improves dimensional stability in service.

Hold for one second and then slowly breathe out through your nose as you count to three again. Stainless Steel - Grade 316 Grade 316 316L Technical Data Summary. In this paper a new stress relieving method based on ultrasonic vibrations is introduced which is applicable on the small or thin parts.

Stress Relief Stress relief is one of the most common heat-treating processes used in spring manufacturing. The normalizing process is designed to relieve stresses which results in improved ductility and toughness. The effectiveness of the method was verified by comparing it with thermal stress reliving.

In addition to excellent corrosion resistance and strength properties Types 316 and 316L alloys also provide the excellent fabricability and formability which are typical of the austenitic stainless steels. Imagine that air spreading throughout your body. Stress Relieving Temperature When the weldment of 316 grade stainless steel is not suitable for complete annealing the residual stress can be moderately lowered below 600 C which makes it have good creep resistance.

Breathe in through your nose and imagine that youre inhaling peaceful calm air. These grades are well suited for fabricated or formed applications like refining equipment surgical tools fasteners pulp and paper processing equipment and pharmaceutical processing. Stress Relieving 304316 SS.

These stresses can cause loss of tolerance cracking. These alloys also offer higher creep stress-to-rupture and tensile strength at elevated temperature. PWHT of SS would normally only be used to homogenize the microstructure solution annealing.

Both grade 316 and 316L steels offer high creep strength stress-to-rupture and tensile strength at high temperatures as well as excellent corrosion resistance and strength properties. Drawing forming and machining induce stresses in all wire products. Stress relieve 316 forging EdStainless Materials 21 Oct 04 0942 If you are only working at 200C I would still give it a few cycles to 250C before final machining.

Without it subsequent processing may give rise to unacceptable distortion andor the material can suffer from service problems such as stress corrosion cracking. Full solution treatment annealing generally by heating to about 1975F 1080C followed by rapid cooling. Like any manufacturing step if not performed properly this simple operation can have disastrous consequences.

Not generally as stress relief.

Grade 316 Stainless Steel Austral Wright

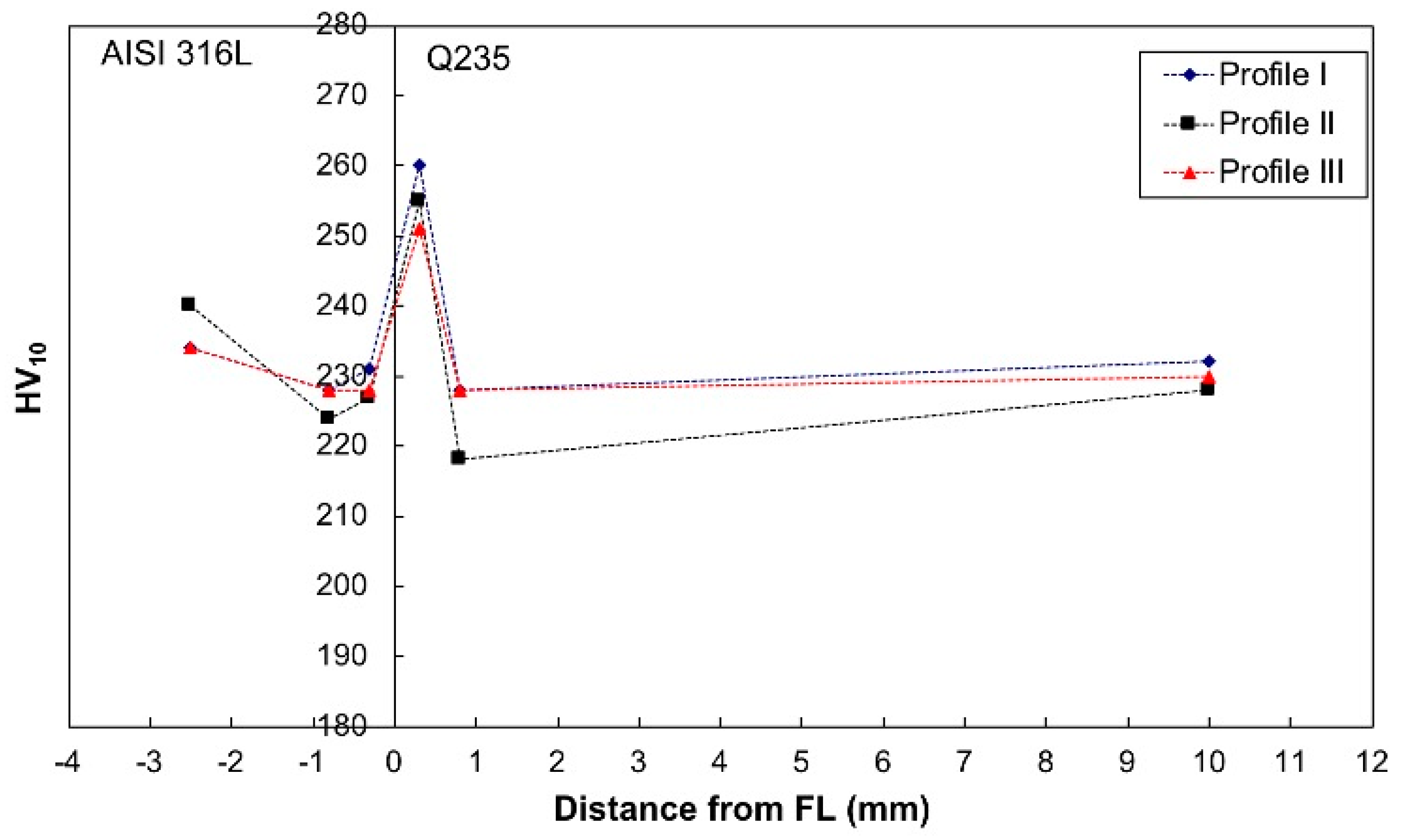

Metals Free Full Text Corrosion Behavior And Mechanical Properties Of Aisi 316 Stainless Steel Clad Q235 Plate Html

Metals Free Full Text Corrosion Behavior And Mechanical Properties Of Aisi 316 Stainless Steel Clad Q235 Plate Html

Http Heat Treat Doctor Com Documents Stress 20relief Pdf

Https Dl Asminternational Org Handbooks Book Chapter Pdf 235041 A0005782 Pdf

Pin By Vitality Living On Stress Relief How To Relieve Stress Stress Stress Reduction

0 Comments