The stress relaxation of heat treated nickel-based superalloy Inconel 718 at 1 strain and high temperature was investigated. They are hardened only by cold work and are machined most readily in the cold-drawn or cold-drawn and stress-relieved condition.

Microstructural Changes During Stress Relief Heat Treatment Of Inconel 625 A106 Carbon Steel Joint Springerlink

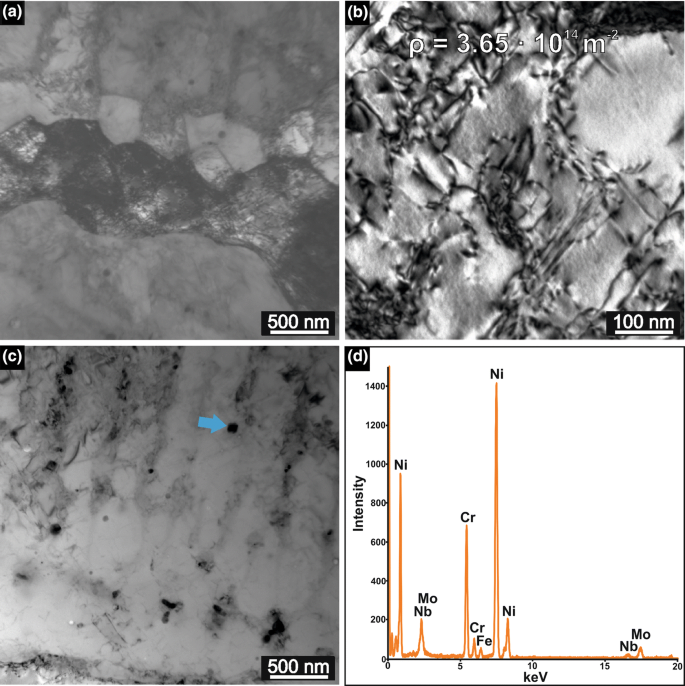

The microstructural evolution of laser powder-bed additively manufactured Inconel 625 during a post-build stress-relief anneal of 1 h at 870 C is investigated.

Stress relief inconel 625. The results of the tensile test revealed that all of the samples have been fractured at A106 alloy HAZ the reason of which is the higher strength of the Inconel alloy. Specialist in hard to Locate Nickel Alloy Inconel material. It is found that this industry-recommended heat treatment promotes the formation of a significant fraction of the orthorhombic D0a Ni3Nb delta-phase.

After measurement of stressed lattice spacings in Inconel 625 walls reference samples were obtained by extracting thin slices from the walls and cutting comb-type slits into these slices. The precipitation of carbides depletes the matrix of carbon resulting in a smaller lattice spacing in the heat-treated samples. Usually welded with Ni-Cr-X alloys but more nearly matching consumables are available which contain higher C and also Nb.

By applying stress relief treatment even at the lowest. This phase is known to have a deleterious influence on fracture toughness. Ad Supplier of Inconel 600 601 622 625 686 690 706 718 Hx L605 X750 Material.

The microstructural evolution of laser powder-bed additively manufactured Inconel 625 during a post-build stress-relief anneal of 1 hour at 1143 K 870 C is investigated. These alloys include nickel 270 monel K-500 unaged inconel 600 601 690 nimonic 75 86 incoloy 800 800HT 802 825 DS inco 330 020. Materials Research Express 62019 086582.

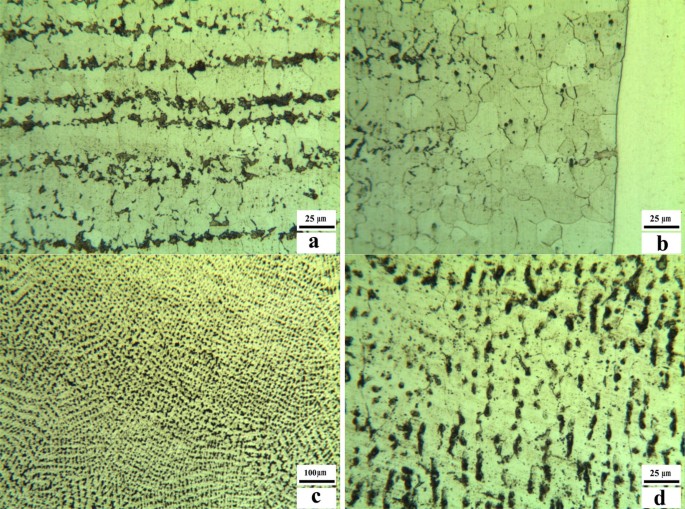

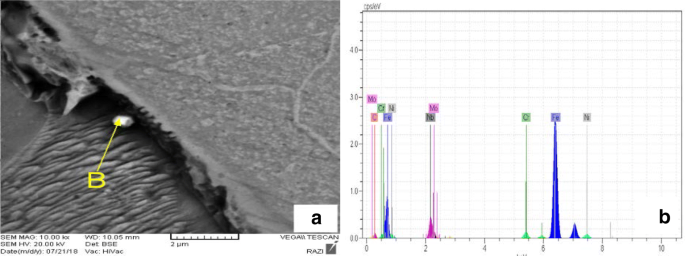

The present study investigates the effect of stress relief treatment at different temperatures 900 1040 and 1200 C on the microstructure of Inconel 625 and A106 carbon steel weld joints. A study on the effect of stress relief heat treatment on the microstructure and mechanical properties of dissimilar GTAW weld joints of Inconel 625 and A106 carbon steel. At HAZ of Inconel 625 hardness also gradually decreases from 210 HV to 192 HV by increasing the stress-relief temperature.

Stress-relieving temperatures for nickel and nickel alloys from 425 to 870C depending on alloy composition and degree of work hardening. Stress corrosion cracking is possible. Solution treatment was applied on the as-received material at 980C for 1 h before water quenched followed by double aging treatments at 720 and 621C for 8 h respectively and then cooled in air.

For such service thermal stress relief is applied after welding. The present study investigates the effect of stress relief treatment at different temperatures 900 1040 and 1200 C on the microstructure of Inconel 625 and A106 carbon steel weld joints. A heat treatment used to remove or reduce stresses in work-hardened non-age-hardenable alloys without producing a recrystalized grain structure.

The results of the study show that due to the generation of heat by welding the bainite phase was formed in the heat-affected zone of A106 alloy. It is found that this industry-recommended heat treatment promotes the formation of a significant fraction of the orthorhombic D0 a Ni 3 Nb δ-phase. Stress corrosion can also occur in Ni-Cr alloys in high.

Consists primarily of the age-hardenable alloys has two subgroups. Inconel 625 Thermanit 2133. Reference lattice spacings were measured in these slices as well as equivalent slices that were also subjected to stress-relieving heat treatment.

Specialist in hard to Locate Nickel Alloy Inconel material. Ad Supplier of Inconel 600 601 622 625 686 690 706 718 Hx L605 X750 Material. Carbides tend to form when Inconel 625 is heated at 870 C for 1 h which was the heat treatment performed to relieve stresses in one set of reference samples.

The results of the study show that due to the generation of heat by welding the bainite phase was formed in the heat-affected zone of A106 alloy. The Inconel is inlayed into 4130 steel and then put through a stress relief cycle of 1175 deg F for 3 hrs. I have many projects that require Inconel 625 to be weld inlayed into various oilfield equipment valves etc.

Hexagon Socket Cap Screws And Fasteners Hexagon Screws Fasteners

Pdf Microstructural Changes In Inconel 625 Alloy Fabricated By Laser Based Powder Bed Fusion Process And Subjected To High Temperature Annealing

Microstructural Changes During Stress Relief Heat Treatment Of Inconel 625 A106 Carbon Steel Joint Springerlink

Microstructural Changes In Inconel 625 Alloy Fabricated By Laser Based Powder Bed Fusion Process And Subjected To High Temperature Annealing Springerlink

Microstructure Of The L Pbf Inconel 625 After Stress Relief Annealing Download Scientific Diagram

Microstructure Of The L Pbf Inconel 625 After Stress Relief Annealing Download Scientific Diagram

0 Comments