The hot steel is allowed to cool. Figure 10 Jominy Hardenability Curve for 4140 and 4140HW The data represents an average of Jominy results from several 4140 and 4140HW heats.

Practical Machinist Largest Manufacturing Technology Forum On The Web

Temper 540-680 o C hold for 1 hour min.

Stress relieve 4140. In the annealed condition 600-650 o C. As the title suggests it reduces the residual stresses that may have been caused by hot rolling welding or cutting. Another heat treat process for steel is stress relieving.

Tempering is carried out to relieve stresses from the hardening process but primarily to obtain the required mechanical properties. Harden 830-860 o C Oil quench. By RonG Date 02-06-2009 2229.

Max 200FHr updown ramp above 600F. It is preferred that welding be carried out on 4140 while in the annealed condition and that the work piece immediately on cooling to hand warm is then stress relieved at 595 o C - 620 o C prior to hardening and temperingIf welding in the hardened and tempered condition is really necessary then the work piece immediately on cooling to hand warm should be stress relieved at 15 o C below the. The actual tempering temperature will be.

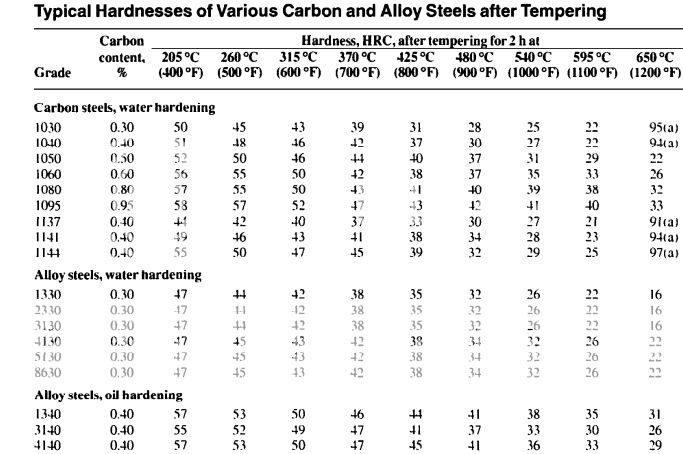

Apart from these two there are other elements that are added. AISI 4140 alloy steel is annealed at 872C 1600F followed by slowly cooling in the furnace. AISI 4140 alloy steel can be tempered at 205 to 649C 400 to 1200F depending upon the desired hardness level.

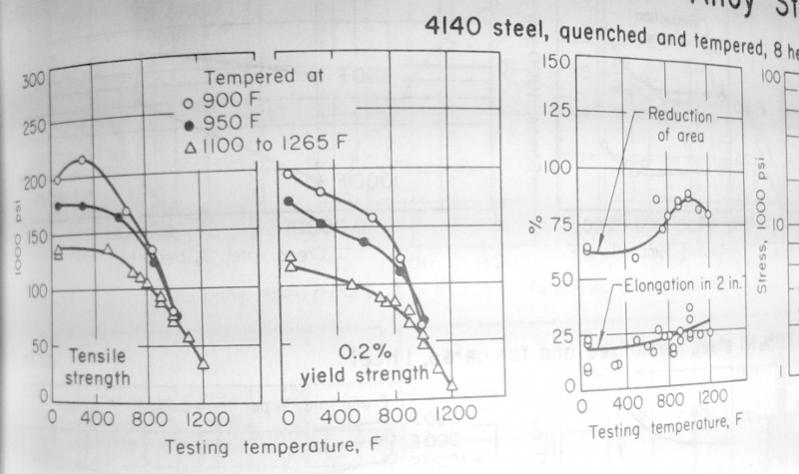

Stress Relieving 4140 post weld. Figure 9 Mechanical Properties for 4140 and 4140HW The data represents a mechanical property comparison of several 4140 and 4140HW heats. This lowers the hardness to the 28-32 RC range that we are looking for.

The nice part about this process is that it does not change hardness at all nor does it. They turn into a molten state and combine to form one solid metal. 90Ksi would not be heat treated material so I offer this.

The major alloys of 4140 steel are carbon and iron. This process improves machinability and reduces stress to decrease the likelihood of cracking during cold working operations. That will de-temper the pre-hard into the low 30 HRc but Pre Hard is usually 29 -.

With this process the steel is heated to a temperature below the critical temperature resulting in little to no change to the material properties like there is with annealing and normalizing. 4140 Annealing Stress Relieving. If you want to stress relieve to assure machine stability shape stabilization or to reduce premature fatigue then I suggest that you could use sub-harmonic stress relief on your 4140 tubes.

SAE 4140 AISI 4140 steel is a Cr-Mo series Chrome molybdenum series low alloy steel this material has high strength and hardenability good toughness small deformation during quenching high creep strength and long-lasting strength at high temperature. Stress relieve below the tempering temperature. See tempering chart Nitride Suitable for both liquid and gas nitriding.

These elements are placed in an electric furnace or even in an oxygen furnace. SAE AISI 4140 Alloy Steel. To relieve these stresses and to reduce the degree of hardness to an appropriate level the steel is then tempered or drawn by reheating to 1000F again for 4140 or equal.

Austenitizing should ensure all micro-constituents in the steel are transformed to austenite. That welding be carried out on 4140 while in the annealed condition and that the work piece immediately on cooling to hand warm is then stress relieved at 595 oC - 620 C prior to hardening and temperingIf welding in the hardened and tempered condition is really necessary then the work piece immediately on cooling to hand warm should be stress. Alloying elements include chromium and molybdenum and as a result these materials are often informally referred to as chromoly steel common variant stylings include chrome-moly CrMo CRMO CR-MOLY and similar.

It is recommended that 4140 Annealed be stress relieved at 50F below the final tool tempering temperature after the EDM process to temper the rehardened layer produced by EDM. Smaller sections of 4140 might be quenched in oil heavier sections in water. Most of the time the PWHT stress relief temp will be 1050F 1hourinch max cross section.

AISI SAE 4140 alloy steel can be made into round steel bar flat square steel bar. With an on-site 8 x 8 x 14 car-bottom furnace PGI Steel anneals parts cut from 4140. With proper furnace heating techniques AISI 4140 maintains its properties through exposure to the relatively high heating temperatures during annealing or stress relieving.

Sub-Critical Annealing is a relatively low temperature heat treating process used to reduce hardness and increase ductility. AISI 4140 alloy steel can be cold worked using conventional methods in the annealed condition. But 4140 Stress relief is around 1100 - 1300F depending on hold time.

At temperature air cool. These are manganese chromium and molybdenum. This treatment should be performed on higher carbon material grades such as 1045 or 4140.

Alro stocks 4140 CF QT -a steel in the family of SAE steel grades as specified by the Society of Automotive Engineers SAE.

Tensile Stress Strain Curves Of Tig Welded Aisi 4140 Steel Download Scientific Diagram

Practical Machinist Largest Manufacturing Technology Forum On The Web

Practical Machinist Largest Manufacturing Technology Forum On The Web

Practical Machinist Largest Manufacturing Technology Forum On The Web

Microstructures Of Aisi 4140 Steel A As Received Specimen 500x B Download Scientific Diagram

Practical Machinist Largest Manufacturing Technology Forum On The Web

0 Comments