Sometimes machining processes are enough to relax the material. Usually for AA 6061 alloy stress relieving is performed by re-heating the parts at 343C for 1 h.

Https Www Tandfonline Com Doi Pdf 10 1080 02670836 2016 1243335

The stress-relief process must begin within 2 hours of the quench carried out in step 2.

Stress relieve 6061 aluminum. But the spec called for a temp at about 341C 645F. Abbreviated as VSR this non-thermal stress relief method is used in metalworking to enhance dimensional stability and mechanical integrity especially for aluminum that has been cast forged or welded. 6061 T9 aluminum temper.

The cooling curves of 6061 aluminum alloy were obtained in water quenching. It is suitable for 6061 aluminum products processed by cold processing or straightening and leveling to increase strength. Solution-treated AA 6061 alloy contains residual stresses which cause unwanted deformation during the machining operation rendering the parts unacceptable for use.

Both treatments are shown to affect the size and number of the. How long that takes depends on a lot of factors. The ultimate tensile strength is the maximum on the engineering stress-strain curve.

Cool in still air. Part is cold stabilized in a liquid nitrogen bath for 30 to. 6061 can be partially annealed with the torch but to do so means that the resultant temper when it naturally age hardens back again will only be very roughly approximate.

Increasing the workability of the material. I dont believe you can take all the stress out of aluminum. This corresponds to the maximum stress that can be sustained by a structure in tension.

Cryogenic Testing Of Reflective Optical Components And Telescope Systems The substrate material was 6061 - T6 aluminum that was machined and stress relieved for optimum stability per an SSG process control specification. Most parts have been made of 6061 - T6 Aluminum heat treated to relieve stresses in the substrate before diamond. Soak for 2 hours min for 5 inch thickness add 5 hour for every addl 5 inch part thickness.

Steel Saw Cutting catalog including Item ThicknessWidthLengthEstimated Weight per Sq. There was a description within an email that also gave a maximum exposure time for the different aluminum alloys. The fatigue strength of 6061 aluminum alloy is 965 Mpa 14000 psi which is calculated using 500000000 cycles of continuous cyclical loading below the yield point.

One of the popular methods is known as vibratory stress relief. The stress-relief cycle consists of the following steps. In the natural world all things come to equalization.

Part is to be stress-relieved by means of 4 cycles of cold stabilization followed by boiling-water quench. 6061 T10 aluminum temper. Based on the cooling curves the HTC curves were solved.

6061 is perhaps the best place to start because it is the most forgiving of transgressions. Ultimate tensile strength of 6061 aluminium alloy depends greatly on the temper of the material but for T6 temper it is about 290 MPa. For 6061 the maximum exposure time was 100 hours a 350F 10 hours.

It is suitable for the products whose strength is improved by cold working. LLE Review quarterly report July--September 1993. 6061 aluminum the electricity not only further reduces the specific energy and flow stress but also delays the onset of necking.

Soot the area to be annealed as we have discussed or use a crayon to bring it up to 650F and quench with cold. Ive stress relieved 6061 by putting it in an oven after roughing at 375 for 6hrs. The temper of artificial aging after solution heat treatment and then cold working.

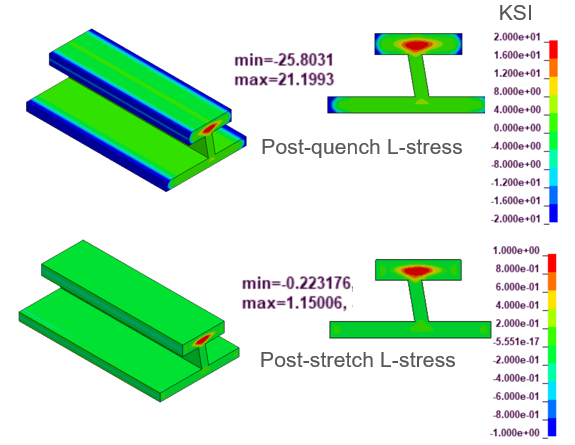

Manufacturers have more options than heat treating to relieve stress in aluminum alloys. The temperature and stress distributions of a circular pipe of 6061 aluminum alloy were simulated by ABAQUS software and the basis for preferable quenching techniques was offered. Stress relieving is a form heat treating also known as annealing that describes a variety of processes designed to alter the physical and perhaps even the chemical properties of a metal in order to increase its ductility and reduce its hardness so that it is more workable.

When all of the stresses have equalized it will quit moving - given a stable temperature. Prior to final machining stress relieve at 350 degress F for 8 to 10 hours. 2 Experimental 21 Quench experiment 6061 aluminum alloy was used for quenching.

This effect is illustrated in Figure 1 which shows that a 250 F 121 C exposure for periods as long as 50 hours will not effectively reduce the yield strength of a 7000 series aluminum alloy 1. Stress relief should be at 230C for a minimum of 12 hours at saturation temp with natural cooling to room temperature. These values are summarized in Table 1.

They said that typically 6061-T6 is treated at about 177C 350F for stress relieve. Heat and cold play a major factor. FtEstimated Weight per Seet.

The telescope mirrors are made of 6061 -T6 stress - relieved aluminum coated with a layer of electroless nickel underlying a layer of reflective gold. Summary of mechanical properties for 6061 aluminum alloy. Even for prolonged exposures up to temperatures of 300 F 149 C and 350 F.

The precipitates and grains of the aluminum are investigated for alterations due to either annealing or electrical flow. Browse 6061-T651 Heat Treated Aged Stress-Relieved Aluminum Alloys - Plate in the Fay Industries Inc.

Pdf Effects Of Solution Temperature And Time On Microstructure And Properties Of A 6061 Aluminum Alloy

Stress Relieving Processes For Aluminum Alloys Clinton Aluminum

Stress Relieving For Sheets And Plates Clinton Aluminum

Mechanical Stress Relief Of Aluminum Alloys Hill Engineering

Https Www Tandfonline Com Doi Pdf 10 1080 02670836 2016 1243335

0 Comments