This process improves machinability and reduces stress to decrease the likelihood of cracking during cold working operations. These stresses can cause loss of tolerance cracking.

Aisi 4140 Steel Fatigue Performance Cd Replacement By Electroplated Zn Ni Alloy Coating Springerlink

It is recommended that 4140 Annealed be stress relieved at 50F below the final tool tempering temperature after the EDM process to temper the rehardened layer produced by EDM.

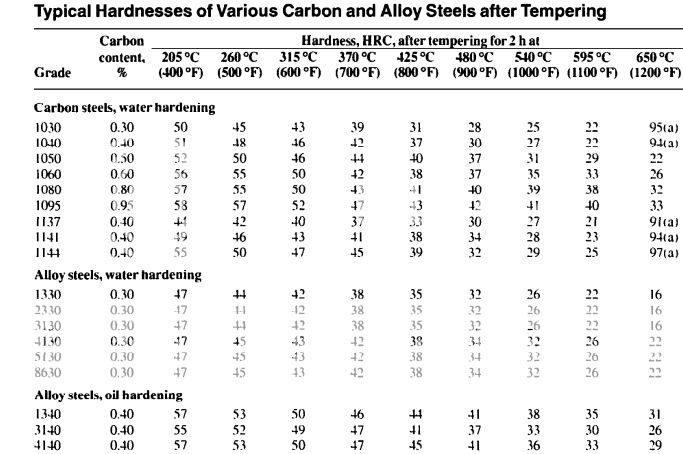

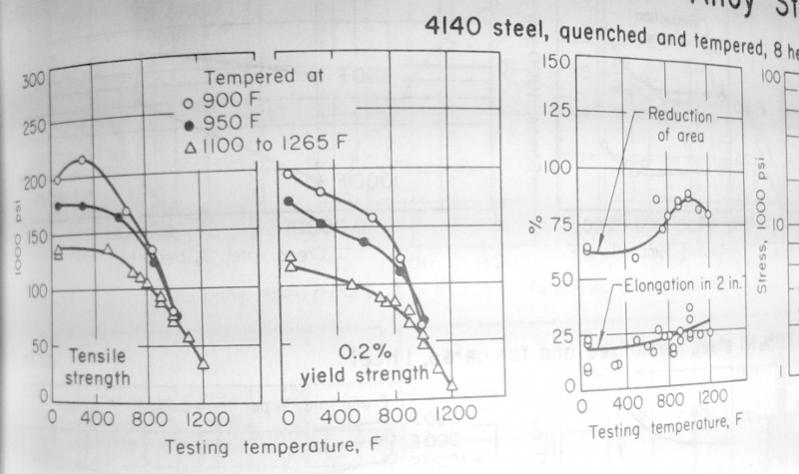

Stress relief 4140. The heat treat process is used to change physical or chemical properties of a material through austenitizing heating material to a high temperature quenching quick cooling of material and tempering reheating plate at a relatively low temperature to improve. AISI 4140 alloy steel can be tempered at 205 to 649C 400 to 1200F depending upon the desired hardness level. If you want to stress relieve to assure machine stability shape stabilization or to reduce premature fatigue then I suggest that you could use sub-harmonic stress relief on your 4140 tubes.

To relieve these stresses and to reduce the degree of hardness to an appropriate level the steel is then tempered or drawn by reheating to 1000F again for 4140 or equal. In certain applications internal residual stresses can sum up with those generated by externally applied loads. Alloying elements include chromium and molybdenum and as a result these materials are often informally referred to as chromoly steel common variant stylings include chrome-moly CrMo CRMO CR-MOLY.

4140 CF QT SR Alloy Alro stocks 4140 CF QT -a steel in the family of SAE steel grades as specified by the Society of Automotive Engineers SAE. This process can relieve over 90 the internal stress within steel and is particularly useful for large cast or welded parts in addition to workpieces from which a lot of material was removed during machining. AISI 4140 is a chromium-molybdenum alloy steel.

That welding be carried out on 4140 while in the annealed condition and that the work piece immediately on cooling to hand warm is then stress relieved at 595 oC - 620 C prior to hardening and temperingIf welding in the hardened and tempered condition is really necessary then the work piece immediately on cooling to hand warm should be stress. Removing or reducing the residual stresses generated by welding is required for improving the dimensional stability of weldments. Harde ning For higher strength pre-heat to 1250ºF for one hour.

Stress relieving steel is one way to deal with this situation and machined steel parts may warp or crack during use if this type of action is not taken. Stress relieving before nitrocarburising should be executed at temperatures 600C. This treatment should be performed on higher carbon material grades such as 1045 or 4140.

That will de-temper the pre-hard into the low 30 HRc but Pre Hard is usually 29 - 32 Rockwell so. But 4140 Stress relief is around 1100 - 1300F depending on hold time. 4340 heat treat Normalizing.

The nice part about this process is that it does not change hardness at all nor does it. But 4140 Stress relief is around 1100 - 1300F depending on hold time. By RonG Date 02-06-2009 2229.

For stainless steels a high temperature solution heat treatment is normally necessary. Alloy steel 4340 heat treatment including. The stress relieving temperature is normally between 550 and 650C for steel parts.

Sub-Critical Annealing is a relatively low temperature heat treating process used to reduce hardness and increase ductility. Stress Relieving 4140 post weld. Copper and brass components can also be stress relieved.

Most of the time the PWHT stress relief temp will be 1050F 1hourinch max cross section. Anne aling Prior to rehardening anneal 4140 PH at 1450º -1550F for 4 hours. Stress-relieving is the process generally specified after welding of most materials.

Heat to 845 to 900 C 1550 to 1650 F and hold for a period of time which depends on the thickness of the section. Air or furnace cool to room temperature. This process leaves the steel in a full hard state too hard to use for making rifle barrels not to mention full of stresses.

The chromium content provides good hardness penetration and the molybdenum content ensures uniform hardness and. AISI 4140 alloy steel can be cold worked using conventional methods in the annealed condition. That will de-temper the pre-hard into the low 30 HRc but Pre Hard is usually 29 -.

Stress Relief Heat 4140 PH sl owly and uniformly to 900F. Stress Relieving Annealing Normalizing Nitriding Tempering Flame and Induction Hardening Hardening Applications. Stress Relief Stress relief is one of the most common heat-treating processes used in spring manufacturing.

Soaking time is about one to two hours. Cool slowly 50Fhr to 1200F then air cool. Thus if we have a 4140 steel part 4140 has a 1380oF Ac1 that we want to stress relieve we could place it in our Cress furnace take it up to 1100oF and soak it for 6 hours followed by controlled cooling at a rate of lowering it at 50 to 75oF per hour in a closed furnace to below 400oF at which point it can be removed from the furnace and it would be stress relieved.

AISI 4140 alloy steel is annealed at 872C 1600F followed by slowly cooling in the furnace. Normalizing annealing hardening tempering spheroidization stress relief etc. 90Ksi would not be heat treated material so I offer this.

Like any manufacturing step if not performed properly this simple operation can have disastrous consequences. Drawing forming and machining induce stresses in all wire products. In order to understand what annealing normalizing and stress relieving is we first need to understand what heat treatment is.

Allow piece to soak 1 hourinch of section thickness. Max 200FHr updown ramp above 600F.

.jpg)

Aisi 4140 Alloy Steel Uns G41400

Practical Machinist Largest Manufacturing Technology Forum On The Web

Effect Of Stress Relief Temperature On The Strength Coefficient Of Aisi Download Scientific Diagram

Practical Machinist Largest Manufacturing Technology Forum On The Web

Effect Of Post Weld Heat Treatment And Electrolytic Plasma Processing On Tungsten Inert Gas Welded Aisi 4140 Alloy Steel Sciencedirect

Microstructures Of Aisi 4140 Steel A As Received Specimen 500x B Download Scientific Diagram

0 Comments